In the world of construction and beyond, mini excavators have carved out their niche as indispensable tools. These compact powerhouses have reshaped how professionals and DIY enthusiasts tackle various projects, offering versatility and efficiency in a small package. Whether you’re leveling a backyard or maneuvering through a bustling construction site, understanding mini excavators can unlock new possibilities. This guide unearths the secrets to mastering mini excavators, covering everything from their history to future trends.

A Brief History of Mini Excavators

Mini excavators, though a modern marvel, have roots dating back to the late 1960s. Their creation was driven by the need for versatile, smaller machinery capable of performing tasks that larger equipment couldn’t nimbleness without compromising power. Fast forward to today, they play a crucial role in construction and DIY projects worldwide.

Their ability to work in tight spaces and handle diverse tasks makes them indispensable. From urban landscaping to rural construction sites, mini excavators have become synonymous with efficiency. Their relevance continues to grow as more industries recognize their potential.

Key Features of Mini Excavators

Understanding the key features of mini excavators is essential for leveraging their full potential. One of the most significant advantages is their compact size, which allows them to efficiently navigate confined spaces that larger machines cannot access. This manoeuvrability is paired with impressive lifting capabilities, enabling operators to handle various loads with confidence. Additionally, mini excavators often come equipped with advanced hydraulic systems that enhance their performance, providing superior power and control.

Furthermore, modern mini excavators boast user-friendly controls, often including intuitive joysticks and ergonomic seating arrangements, which facilitate ease of use for both seasoned operators and novices. The availability of interchangeable attachments—from hydraulic thumbs to augers—further amplifies their versatility, making them suitable for an array of tasks, such as digging, trenching, and demolition. These features collectively position mini excavators as indispensable assets across multiple sectors, driving productivity and efficiency in every application.

Advantages of Using Mini Excavators

The advantages of employing mini excavators in various projects are substantial and manifold. First and foremost, their reduced size and weight contribute to increased accessibility in tight and confined spaces, enabling operations in areas where larger machinery simply cannot operate.

This agility significantly cuts down on project timelines, allowing tasks to be completed more expeditiously. Moreover, mini excavators consume less fuel compared to their larger counterparts, making them a cost-effective choice for both contractors and DIY enthusiasts alike. This fuel efficiency aligns with the growing emphasis on sustainability within the construction sector, as operators strive for environmentally friendly alternatives without compromising performance.

Additionally, mini excavators are known for their ease of transport. Their compact design enables simpler transportation to and from job sites, often eliminating the need for large trailers or specialized transport equipment. This portability means that equipment can be brought directly to the job at hand, minimizing downtime and maximizing productivity.

The adaptability of mini excavators, combined with their range of attachments, allows them to seamlessly transition between tasks—such as digging, grading, or lifting—making them unrivalled in their capability to meet a diverse array of project demands. Ultimately, their strategic advantages underscore why mini excavators have become essential tools in modern construction and landscaping projects.

Types and Sizes of Mini Excavators

Mini excavators come in various types and sizes, tailored to different tasks and terrains. Typically, these machines are classified by their weight and digging depth. For light landscaping, a compact mini excavator under 3 tons is ideal, while larger models, ranging from 3 to 10 tons, suit heavier construction tasks. The choice of size also depends on the job site’s characteristics.

For instance, urban projects require smaller machines to maneuver through narrow spaces, whereas rural projects benefit from larger models with extended reach and lifting capabilities. Understanding these variations helps you select the right tool for the job.

Selecting the Right Mini Excavator for Your Project

Choosing the appropriate mini excavator for your specific project is critical to achieving optimal results. Begin by assessing the scope and nature of the work at hand. For tasks involving extensive digging or heavy lifting, a more robust model that offers greater stability and lifting capacity may be necessary. Conversely, for projects requiring precision in tight spaces, a lighter, more compact excavator is advisable.

Consider also the terrain and soil conditions where the excavator will operate. Soft, uneven ground may necessitate a machine equipped with wider tracks to distribute weight and prevent sinking, while rocky or hilly conditions might benefit from an excavator with enhanced power and digging depth.

Additionally, be aware of the attachments required for your specific tasks. Options such as buckets, breakers, or tilt-rotators can enhance versatility and efficiency, allowing for a seamless adaptation to various tasks—from excavation to demolition.

Finally, ensure that you account for operator comfort and control features. Advanced models with ergonomic seating, adjustable controls, and high-visibility cabs will not only enhance productivity but also ensure safer operation. Equip yourself with the knowledge to select the right mini excavator, and you will undoubtedly pave the way for successful project execution and outstanding results.

Maintenance and Care for Mini Excavators

Proper maintenance and care of mini excavators are vital to ensure their longevity and optimal performance. Routine inspections should be carried out to check essential components such as hydraulic fluid levels, track tension, and engine performance.

Regularly cleaning the filters and radiators is necessary to prevent overheating and maintain efficiency, while scheduled lubrication of moving parts reduces wear and tear, contributing to the machine’s overall reliability.

Additionally, it’s important to establish a maintenance schedule in alignment with the manufacturer’s recommendations, which may include addressing wear items such as undercarriage components and hydraulic hoses.

Keeping a detailed log of maintenance activities not only helps in tracking performance but also assists in identifying potential issues before they escalate into more significant problems. By diligently maintaining mini excavators, operators can enhance their operational lifespan and ensure they remain dependable assets, capable of meeting the demands of various projects effectively.

Ultimately, embracing a proactive approach to maintenance reflects a commitment to excellence, thereby maximizing the investment in mini excavators and solidifying their role as indispensable tools in the construction and landscaping industries.

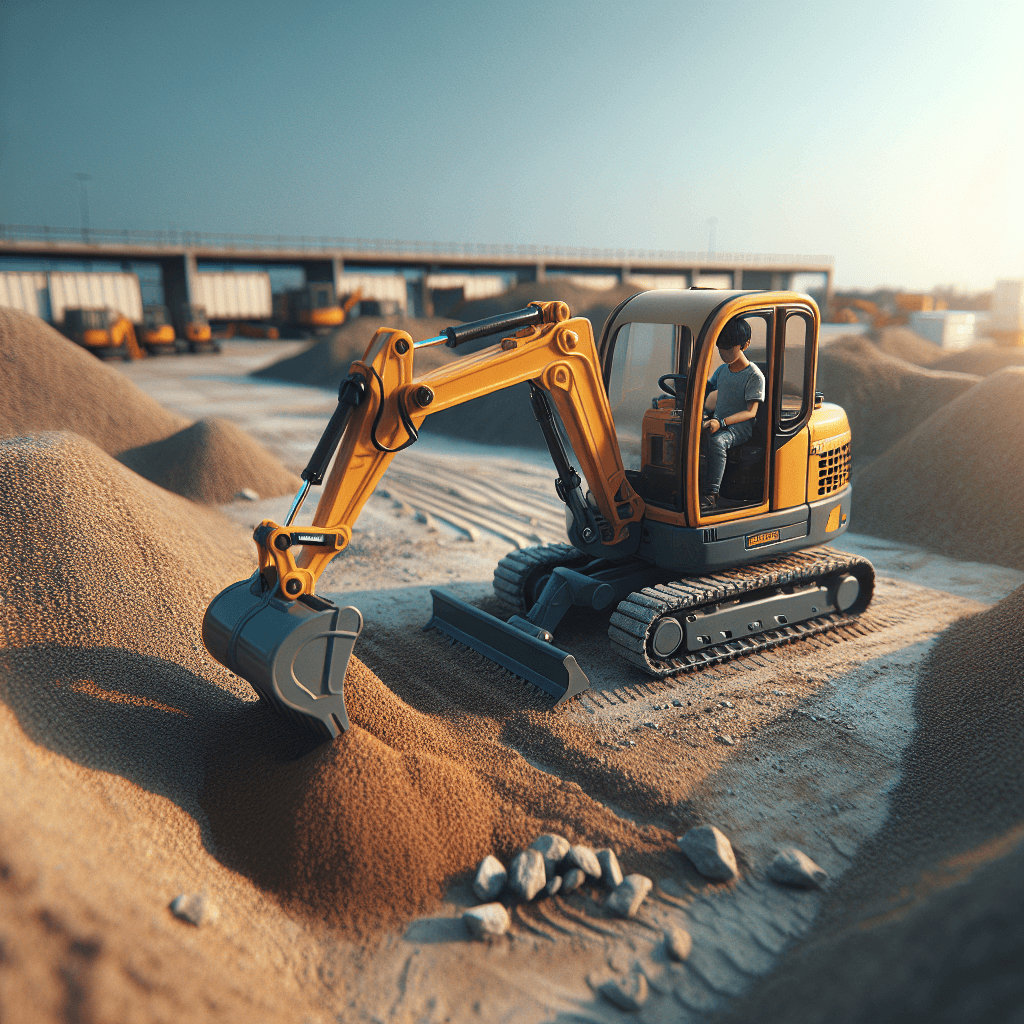

Operating a Mini Excavator A Beginner’s Guide

Operating a mini excavator may seem daunting, but with the right guidance, it’s a skill anyone can master. Start by familiarizing yourself with the controls—joysticks for movement and levers for the boom and bucket. Safety is paramount, so always wear protective gear and follow manufacturer instructions.

Before starting the engine, perform a thorough pre-operation inspection, checking fluid levels, tire pressure, and attachments. Once you’re ready, practice gentle maneuvers in an open area. Gradually increase complexity as you gain confidence. With time, you’ll become proficient in tasks like digging, lifting, and trenching.

Essential Maintenance Tips for Mini Excavators

Maintenance is the backbone of any machinery’s longevity, and mini excavators are no exception. Regular upkeep ensures optimal performance and prevents costly breakdowns. Begin with routine inspections, focusing on the hydraulic system, tracks, and attachments. Cleaning is crucial, especially after dusty or muddy jobs, to prevent clogging and wear.

Always check fluid levels and replace filters as needed. Lubricate moving parts to reduce friction and extend lifespan. Lastly, keep a maintenance log to track repairs and servicing dates. Adhering to these practices will keep your mini excavator in peak condition, ready for any challenge.

Maintenance Tips for Mini Excavator Owners

For mini excavator owners, implementing a rigorous maintenance routine is essential to ensure the machine remains a reliable asset. First and foremost, always refer to the manufacturer’s manual for specific maintenance intervals tailored to your model, as this will guide you in scheduling regular inspections and checks.

Beyond the standard routine, focus on monitoring the hydraulic system closely, as any irregularities in performance could indicate leaks or pressure issues. It’s advisable to inspect hoses and connections for signs of wear or damage regularly. Additionally, cleaning the undercarriage and tracks after each use not only prevents the accumulation of dirt and debris but also allows for better mobility and performance in subsequent tasks.

Be proactive in tracking fluid levels, ensuring the engine oil, hydraulic fluid, and coolant are maintained at optimal levels. Regularly changing the oil and filters according to the recommended schedule is critical for longevity and efficiency. Furthermore, pay attention to the condition of the bucket and other attachments; sharp blades and durable components not only enhance performance but also reduce strain on the machine.

Lastly, understand the importance of operator training. Investing in training for yourself or your operators can lead to more efficient handling of the machinery, decreasing the likelihood of accidents or misuse that may cause undue wear and tear. By prioritizing these maintenance practices, mini excavator owners can safeguard their investment and ensure the equipment operates seamlessly for years to come.

Maintenance Requirements for Mini Excavators

To ensure optimal performance and longevity of mini excavators, adherence to comprehensive maintenance requirements is essential. Below are key maintenance tasks outlined in bullet points for clarity:

- Daily Inspections:

- Check hydraulic fluid levels and top up if necessary.

- Inspect tracks for any signs of damage or wear.

- Ensure all safety features are operational.

- Weekly Maintenance:

- Clean filters (air, hydraulic, and fuel) to prevent clogs.

- Examine hoses and fittings for leaks or signs of wear.

- Inspect and clean the undercarriage and tracks.

- Monthly Maintenance:

- Change engine oil and replace oil filters.

- Check and replace fuel filters if required.

- Inspect the condition of the bucket and other attachments.

- Quarterly Maintenance:

- Conduct a thorough inspection of the hydraulic system.

- Lubricate all moving parts, focusing on pivot points and joints.

- Review and tighten any loose bolts or fasteners.

- Annual Maintenance:

- Perform a complete inspection of the electrical system.

- Replace hydraulic hoses and connections as per wear indicators.

- Review the manufacturer’s guidelines for specific annual service recommendations.

Maintaining a structured approach to these requirements not only maximizes the operational lifespan of your mini excavator but also mitigates the risks of unexpected breakdowns and costly repairs. By staying proactive in your maintenance efforts, you ensure that your equipment remains a reliable and efficient tool in your projects.

Maintenance and Operational Tips for Mini Excavators

To maximize the efficiency and lifespan of mini excavators, both maintenance and operational best practices must be integrated into daily routines. First and foremost, operators should maintain a clean working environment for the excavator. Regularly removing debris and mud from the machine reduces the risk of damage and ensures smooth operation.

Operators should also be diligent about performing pre-operation checks, which should include verifying that all controls are functional and that safety mechanisms are in place.

In terms of operational techniques, smooth and deliberate movements are paramount. Rapid, jerky motions can place undue stress on the machine and lead to mechanical failures. Operators should also be aware of their surroundings to avoid potential hazards that could lead to accidents.

Furthermore, utilizing the machine’s full range of motion effectively can enhance performance—practising proper digging and lifting techniques will significantly improve productivity and reduce wear on the equipment.

Finally, staying informed about any updates from the manufacturer regarding operational techniques or maintenance schedules is crucial. This proactive stance not only ensures compliance with safety standards but also fosters a culture of excellence in equipment management.

By incorporating these maintenance and operational tips, mini excavator operators can enhance both the performance and reliability of their machinery, leading to superior project outcomes.

The Great Debate Renting vs. Buying Mini Excavators

Deciding between renting and buying a mini excavator is a common dilemma. Each option offers distinct advantages. Renting provides flexibility for short-term projects, eliminating maintenance and storage hassles. It’s cost-effective if your usage is infrequent. On the other hand, owning a mini excavator suits those with ongoing projects and offers long-term savings.

Consider rental costs, equipment availability, and your project’s duration before making a decision. Assess your needs and budget carefully. While renting offers convenience, ownership grants control and availability whenever you require it.

Comparison Table: Renting vs. Buying Mini Excavators

|

Feature |

Renting |

Buying |

|---|---|---|

|

Initial Cost |

Low upfront costs; rental fees apply |

Higher initial investment |

|

Maintenance |

Typically covered by rental company |

Owner responsible for maintenance |

|

Usage Flexibility |

Ideal for short-term or occasional projects |

Best for long-term and frequent use |

|

Storage |

No need for storage; return when done |

Requires storage space when not in use |

|

Equipment Availability |

Limited to rental company’s inventory |

Full control over the machine and its availability |

|

Depreciation |

No depreciation concerns |

Subject to depreciation over time |

|

Customization |

Usually no ability to customise |

Freedom to outfit with specific attachments |

|

Insurance |

Covered in rental agreement |

Owner must arrange and maintain insurance |

|

Financial Commitment |

No long-term financial commitment |

Long-term investment required |

|

Tax Implications |

Rental fees may be tax-deductible |

Ownership may provide depreciation benefits |

This table highlights the key differences between renting and buying mini excavators, enabling stakeholders to make informed decisions based on their project needs and financial circumstances. Understanding these aspects is critical for aligning equipment choices with overall operational strategies.

Safety Considerations for Mini Excavator Operation

When operating mini excavators, safety must be the top priority to protect both personnel and equipment. Operators should start by wearing appropriate personal protective equipment (PPE), including hard hats, safety glasses, gloves, and steel-toed boots. Additionally, it is imperative to conduct a thorough pre-operation safety check, which includes verifying that all safety devices—such as alarms, lights, and seat belts—are functioning correctly.

Awareness of the working environment is crucial; operators must assess for overhead and underground hazards, including power lines and utility placements, before commencing operation. A clear communication plan should be established among team members, utilizing hand signals or radios to ensure everyone is aware of movements and potential dangers.

Furthermore, proper training and certification of operators cannot be overstated. Only qualified individuals who understand the operational limits and capabilities of the equipment should operate the mini excavator.

It is also important to maintain a safe distance from the excavator’s swing radius and to keep the work area clear of unnecessary personnel. These considerations are instrumental in fostering a culture of safety that protects valuable assets and reduces the likelihood of accidents on site.

Safety Measures During Mini Excavator Operation

Implementing robust safety measures during the operation of mini excavators is essential to safeguarding personnel and enhancing operational efficiency. Before commencing work, operators should ensure that all safety devices are not only operational but also well-understood by the entire team. This includes conducting a comprehensive walk-around inspection to confirm that the machine is free from defects and that fluid levels are adequate.

Establishing a clear zone of operation is paramount; this involves setting up barriers to keep unauthorized personnel away from the machine’s swing radius and worksite. Communication protocols must also be well defined—utilizing two-way radios and hand signals can significantly reduce misunderstandings in a noisy work environment. Operators should follow established excavation protocols, which dictate safe digging practices to prevent accidental strikes on underground utilities.

In addition, training and refreshers on emergency procedures are non-negotiable. Each operator should be well-versed in how to respond to equipment malfunctions or hazardous conditions swiftly and effectively. Regular safety drills reinforce this knowledge and ensure that all team members can act quickly in emergencies. Adopting these comprehensive safety measures not only protects the workforce but also optimizes equipment performance, thereby fostering a culture of responsibility and excellence on site.

Common Mini Excavator Attachments

Mini excavators offer versatility that can be significantly enhanced through the use of various attachments designed for specific tasks. Understanding these attachments is crucial for optimizing equipment performance and ensuring project efficiency.

- Buckets: The most common attachment, buckets come in various sizes and shapes, including standard, narrow, and tilt buckets. Standard buckets are ideal for general digging and excavation, while narrow buckets provide precision for trenching and tight spaces. Tilt buckets allow for better grading and leveling of surfaces.

- Hydraulic Hammer: This attachment is designed for breaking concrete, asphalt, and rock. Its powerful percussive action facilitates demolition work and assists in trenching by breaking through hard materials quickly and efficiently.

- Auger: For tasks that require drilling into the ground, augers are a go-to attachment. They vary in size and can create holes for fencing, planting, or utility installations. This attachment simplifies tasks that would otherwise be labor-intensive.

- Grapple: The grapple attachment is essential for handling and transporting materials. With its claw-like design, it is particularly effective for grabbing large objects such as logs, rocks, or debris, making it invaluable in landscaping and site clean-up tasks.

- Ripper: A ripper attachment is used for breaking up hard soils or rocky terrain. It features a single tooth that penetrates tough surfaces, making it easier to clear land or prepare for further excavation.

- Sweeper: Designed to clean up construction sites, this attachment effectively collects dirt, debris, and trash, ensuring worksites remain safe and organised.

By selecting the appropriate attachments, mini excavator operators can significantly broaden their machine’s capabilities, thus enhancing productivity and enabling the execution of a wider range of projects with greater efficiency.

Comparison of Mini Excavators to Other Equipment

Mini excavators stand out as a preferred choice for various construction and landscaping projects, particularly when compared to larger excavators or alternative machinery. One of their primary advantages is their compact size, which allows for greater maneuverability in confined spaces and urban environments where access is limited.

This agility contrasts sharply with larger excavators, which may require extensive area for operation and are often less versatile in tight situations.

In addition, mini excavators generally operate with a lower weight and reduced ground pressure, making them suitable for delicate tasks in areas with soft or unstable surfaces where heavier equipment might cause significant damage. Conversely, while larger excavators excel in heavy-duty tasks, such as deep excavation or extensive earthmoving projects, their size becomes a liability in spaces where precision is key.

When compared to skid steer loaders, mini excavators offer enhanced digging capabilities due to their articulated boom and a greater range of motion, making them superior for trenching and utility work.

Skid steers, although more versatile for loading and pushing tasks, provide limited excavation functionality. Furthermore, mini excavators typically offer better stability during operation, especially on uneven terrains, due to their design and tracks.

In terms of operational efficiency, mini excavators provide an excellent balance between power and fuel economy, often resulting in lower operating costs for small to medium-sized jobs. Their adaptability with multiple attachments allows operators to handle diverse tasks with a single machine.

Consequently, while larger excavators and other equipment serve their purpose in specific contexts, the mini excavator’s combination of versatility, efficiency, and agility makes it a superior choice for a broad range of applications in modern construction environments.

Environmental Benefits of Mini Excavators

Mini excavators offer significant environmental advantages that contribute to more sustainable construction practices. Their compact design results in a smaller operational footprint, which minimizes soil disruption and reduces the potential for erosion and habitat destruction in sensitive areas. This careful approach to excavation is paramount, especially in urban settings where preserving local ecosystems is essential.

Additionally, the lower weight of mini excavators leads to reduced ground pressure, thereby decreasing the likelihood of damage to existing landscapes. This is particularly important when working in locations with fragile terrain, such as parks or residential gardens. Furthermore, the fuel efficiency of mini excavators often translates to lower emissions compared to larger machinery, thus contributing to cleaner air quality and a reduction in the overall carbon footprint of construction activities.

Moreover, the versatility of mini excavators allows operators to efficiently complete tasks without the need for multiple pieces of equipment, leading to fewer trips to and from job sites.

This consolidation not only enhances productivity but also diminishes traffic and associated emissions, promoting a more environmentally responsible approach to construction and landscaping projects. Emphasizing these environmental benefits reinforces the importance of selecting the right equipment for sustainable project execution.

Cost Considerations for Mini Excavators

When evaluating the use of mini excavators for construction and landscaping projects, cost considerations play a critical role in decision-making. Initially, the purchase price of a mini excavator is typically lower than that of larger excavators, making them an economically feasible option for small to medium-sized operations. However, it is essential to consider not only the upfront investment but also the long-term costs associated with operation, maintenance, and attachment versatility.

Operating costs for mini excavators generally include fuel consumption, maintenance, and repair expenses. Their fuel-efficient engines provide a significant cost advantage, especially for projects that require extended periods of operation. Additionally, the simplicity of maintenance for mini excavators can result in reduced downtime and lower overall maintenance costs compared to larger, more complex machinery.

Another financial aspect to consider is the potential for increased productivity through the use of various attachments. By enabling a single machine to perform multiple tasks, mini excavators can decrease the total number of equipment required on-site, reducing rental or ownership costs. Furthermore, this adaptability can lead to more efficient project completion, mitigating the overall labour costs associated with prolonged timelines.

Finally, while the initial costs and operating expenses are crucial, it is equally important to assess the potential return on investment (ROI) from using mini excavators. Their ability to navigate tight spaces and perform intricate tasks can significantly enhance project outcomes, allowing for greater client satisfaction and repeat business opportunities. By carefully weighing these cost considerations, businesses can make informed decisions regarding the integration of mini excavators into their operations, ensuring both financial viability and project success.

Maintenance and Longevity of Mini Excavators

Proper maintenance is pivotal to ensuring the longevity and optimal performance of mini excavators in a variety of applications. Regular servicing, including fluid checks, filter replacements, and preventive inspections, can significantly reduce the risk of unforeseen breakdowns and extend equipment life. Operators should adhere to the manufacturer’s recommended maintenance schedule, as this not only promotes reliability but also preserves the machine’s warranty.

Additionally, operators should focus on maintaining the hydraulic systems, as these are essential for the performance of the mini excavator. Keeping hydraulic fluid levels adequate and monitoring for leaks are critical aspects of maintenance that can prevent costly repairs. The tracks and undercarriage also require routine inspection; maintaining track tension and ensuring proper wear can enhance stability and traction, particularly in uneven terrain.

Moreover, the longevity of mini excavators is greatly influenced by their operational habits. Gentle operation, particularly when working in sensitive environments or navigating tight spaces, reduces wear and tear. Training operators to use equipment efficiently not only prolongs machine life but also ensures safe and effective project execution. Ultimately, the combination of diligent maintenance practices and careful operation will lead to a robust return on investment, making mini excavators a reliable choice for construction and landscaping professionals.

Cost of Ownership for Mini Excavators

Understanding the cost of ownership for mini excavators is essential for any business aiming to optimise its operational budget. The total cost of ownership (TCO) encompasses not only the initial purchase price but also the ongoing expenses related to financing, depreciation, fuel, maintenance, insurance, and potential repairs. These factors collectively impact the economic viability of investing in mini excavators.

Financing options can significantly influence the overall cost of ownership, with many companies opting for lease agreements to mitigate upfront expenditures. However, it is crucial to account for the long-term implications of financing arrangements, as interest rates and terms can affect total costs over time. Depreciation is another key consideration; mini excavators typically experience a predictable depreciation rate, which should be factored into overall financial planning, especially when considering resale value.

Operational costs, including fuel and maintenance, frequently represent the most significant ongoing expenses. Mini excavators often demonstrate superior fuel efficiency, offering cost savings over larger models. When combined with simplified maintenance routines, businesses can achieve a more predictable and lower operational budget. Insurance costs must also be assessed, as coverage levels may vary based on the machine’s value, usage, and associated risks.

Furthermore, businesses should consider the potential for increased profitability stemming from efficient project execution. Due to their versatility and ease of operation, mini excavators enable faster completion times and the execution of a wider range of tasks, leading to an improved bottom line. By conducting a thorough analysis of all these components, companies can make informed decisions regarding the acquisition and integration of mini excavators, ensuring that the lifecycle costs align with their financial objectives.

Comparison of Mini Excavators with Larger Excavators

When evaluating the efficiency and effectiveness of mini excavators, it is essential to compare their capabilities with those of larger excavators. While larger excavators are often preferred for extensive earth-moving projects due to their power and capacity, mini excavators excel in agility and versatility.

Their compact size allows for operation in confined spaces where larger machinery would struggle or be impractical. This is particularly advantageous in urban construction sites, residential projects, and landscaping tasks.

In terms of fuel consumption, mini excavators generally demonstrate greater fuel efficiency, leading to lower operating costs over time. Conversely, larger excavators, while offering higher lifting capacities and deeper digging potential, come with increased fuel and maintenance expenses.

The simplicity of maintenance associated with mini excavators further enhances their appeal, as they require less frequent servicing compared to their larger counterparts, resulting in greater operational uptime.

Moreover, the initial investment for mini excavators is usually considerably lower than that of larger excavators, making them more accessible for small to mid-sized businesses. Their ability to perform a variety of tasks with the right attachments minimizes the need for multiple machines on-site, thus maximizing return on investment.

Ultimately, while larger excavators hold advantages in specific scenarios, mini excavators provide a practical and cost-effective solution for many applications, ensuring that every project can be executed with precision and efficiency.

What Can You Do with a Mini Excavator?

Mini excavators are a versatile powerhouse, capable of handling an array of tasks across industries. In construction, they excel at digging foundations, trenches, and footings, thanks to attachments like augers and rippers. Farming enthusiasts use them for tilling soil, installing fences, and moving heavy loads, making farm work more efficient. Landscaping professionals appreciate their precision in planting trees, removing debris, and maintaining lawns. Material handling becomes a breeze with their lifting capabilities. These machines prove invaluable for maintenance tasks, from clearing snow to digging utility lines. The possibilities are limited only by your imagination.

How Much Does a Mini Excavator Weigh?

Understanding the weight of mini excavators is crucial for selecting the right model for your needs. Typically, these machines range from 2 to 10 tons, with weight affecting their stability and lifting capacity. Lighter models, under 3 tons, are ideal for delicate surfaces and tight spaces. Heavier models, between 5 and 10 tons, offer increased power for demanding tasks.

Consider the operating weight, which includes fuel, attachments, and the operator’s weight. It’s essential to match the machine’s weight to the project’s requirements, ensuring safe and efficient operation.

How Much Can a Mini Excavator Lift?

The lifting capacity of mini excavators is a key factor in their versatility. On average, they can lift between 1,000 and 1,500 pounds, but larger models can handle up to 10,000 pounds. Several factors influence lifting capacity, including the counterweight, attachments, and hydraulic system.

A well-designed counterweight enhances stability, allowing the machine to lift heavier loads without tipping. Attachments, such as buckets and grapples, also impact weight limits. Consider ground conditions as well; stable terrain supports increased lifting capacity. Always consult the manufacturer’s specifications to ensure safe and efficient lifting operations.

Case Studies Real-Life Success with Mini Excavators

Case studies highlight the real-world impact of mini excavators. In urban construction, a small-scale housing project utilized mini excavators to excavate tight spaces efficiently, reducing labor costs and project timelines. A farming cooperative transformed its operations by adopting mini excavators for soil preparation and livestock maintenance, boosting productivity and profitability.

Meanwhile, a landscaping company enhanced its services by using mini excavators for intricate garden designs, resulting in satisfied clients and repeat business. These examples underscore how mini excavators optimize diverse applications, proving their worth in projects of all sizes and scopes.

Future Trends in Mini Excavator Technology

The future of mini excavator technology promises exciting advancements. Automation and telematics are emerging as game-changers, enhancing precision and reducing operator fatigue. Remote-controlled mini excavators enable tasks in hazardous environments, keeping operators safe.

Electric and hybrid models are gaining traction, aligning with sustainability goals and reducing emissions. Additionally, AI integration offers predictive maintenance, minimizing downtime and extending equipment lifespan. These trends indicate a shift toward smarter, more sustainable construction practices. As technology evolves, mini excavators will continue to transform industries, providing innovative solutions for modern challenges.

Conclusion

In the realm of construction, farming, and landscaping, mini excavators stand as versatile and powerful assets. Their compact size and adaptability make them indispensable for a wide range of tasks, from digging and lifting to precise landscaping work. By understanding the nuances of mini excavators, from choosing the right size to mastering their operation, professionals and enthusiasts alike can unlock their full potential.

Whether you decide to rent or buy, the benefits they bring in terms of efficiency and productivity are undeniable. Explore the possibilities of mini excavators and elevate your projects to new heights. For personalized guidance and to explore our range of mini excavators, contact TYPHON Machinery today.